Frame and Body

The purpose of a vehicle’s frame is to support the body, engine and other components. The frame along with the body is largely responsible for the structural integrity of the vehicle. The wheels and tires through the vehicle’s suspension system support the frame itself.

Engine

When you start your car:

- The power from your battery is used to activate the starter motor.

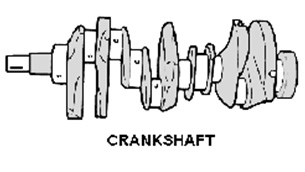

- The starter motor turns the flywheel and crankshaft of the engine so that the engine can attain sufficient momentum and speed to start and run on its own.

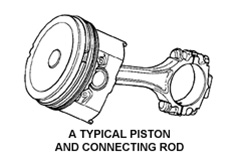

- The crankshaft is inside your engine and it supplies power to the remainder of the power train. The crankshaft is connected by connecting rods to pistons inside cylinders.

- Gas inside the cylinders drives the pistons up and down and through the connecting rods and turns the crankshaft

- Inside the cylinders, a mixture of gas and air is compressed, ignited by the spark plug. The mixture of air and gas is delivered to the cylinders by the carburetor or fuel injection system. Oil is then delivered to all the vehicle’s moving parts to be lubricated. There are

several engine types, which are identified by the number of cylinders and the way the cylinders are laid out. Each cylinder contains a piston that travels up and down inside the cylinder bore. All the pistons in the engine are connected through individual connecting rods to a common crankshaft.

several engine types, which are identified by the number of cylinders and the way the cylinders are laid out. Each cylinder contains a piston that travels up and down inside the cylinder bore. All the pistons in the engine are connected through individual connecting rods to a common crankshaft.

Fuel and Air

The function of the fuel system is to store and supply fuel to the cylinder chamber where it can be mixed with air, vaporized and burned to produce energy. The fuel, which can be either gasoline or diesel, is stored in a fuel tank. A fuel pump draws the fuel from the tank through fuel lines and delivers it through a fuel filter to either a carburetor or fuel injector and then delivered to the cylinder chamber for combustion.

Gasoline

Gasoline is a complex blend of carbon and hydrogen compounds. Additives are added to improve performance. All gasoline is basically the same, but no two blends are identical. The two most important features of gasoline are volatility and resistance to knock (octane).

- Volatility is a measurement of how easily the fuel vaporizes.

- Resistance to knock or octane is simply the temperature at which the gas will burn.

Diesel

Diesel fuel, like gasoline is a complex blend of carbon and hydrogen compounds. It too requires additives for maximum performance. Standard diesel fuel (sometimes called diesel oil) comes in two grades: Diesel #1 (or 1-D) and Diesel #2 (or 2-D). The higher the cetane number, the more volatile the fuel. Most diesel vehicles use fuel with a rating of 40 to 55. You won’t have to worry about which type to use because all diesel automakers specify Diesel #2 for normal driving conditions. Truckers use Diesel #2 to carry heavy loads for long distances at sustained speeds because it’s less volatile than Diesel #1 and provides greater fuel economy. Diesel fuel also is measured by its viscosity. Like any oil, diesel fuel gets thicker and cloudier at lower temperatures. Under extreme conditions, it can become a gel and refuse to flow at all. Diesel #1 flows more easily than Diesel #2, so it’s more efficient at lower temperatures . The two types of oil can be blended, and most service stations offer diesel fuel blended for local weather conditions. 2D fuels are used in warmer weather and are sometimes mixed with 1D fuel to create a competent winter fuel.

Fuel Tank

The Fuel tank is used to store the gas. All tanks have a fuel filler pipe and a fuel outlet line to the engine and a vent system. The catalytic converter cars are equipped with contains a filler pipe restrictor so that leaded fuel, which is dispensed from a thicker nozzle, cannot be introduced into the fuel system. All fuel tanks must be vented.

Fuel Lines

- Steel lines and flexible hoses delete carry the fuel from the tank to the engine. When servicing or replacing the steel lines, steel must be used. Copper or aluminum must never be used.

- When replacing flexible rubber hoses, proper hose must be used. Ordinary rubber such as that used in vacuum or water hose will soften and deteriorate. Be cautious to route all hoses away from the exhaust system.

Fuel Pumps

- There are two types of fuel pumps used in automobiles:

- Mechanical

- Most carbureted cars use mechanical fuel pumps. Mechanical fuel pumps are diaphragm pumps, mounted on the engine and operated by an eccentric cam usually on the camshaft. A rocker arm attached to the eccentric moves up and down flexing the diaphragm and pumping the fuel to the engine. Mechanical pumps operate on pressures of 4-6 psi (pounds per square inch).

- Electric

- All fuel-injected cars today use electric fuel pumps. Electric pumps do not depend on an eccentric for operation. They can be located anywhere on the vehicle but they work best when located near the fuel tank. Electric pumps can operate on pressures of 30-40 psi.

Note: These pumps look identical, so be careful when replacing a fuel pump. Make sure that the proper one is used. Fuel pumps are rated by pressure and volume. When checking fuel pump operation, both specifications must be checked and met.

Fuel Filters

- The fuel filter is the key to a properly functioning fuel delivery system. This applies more with fuel injection than with carbureted cars. Fuel injectors are more susceptible to damage from dirt. When the filter clogs, the electric fuel pump works so hard to push fuel past the filter that it burns itself up.

- Most cars use two filters. One inside the gas tank and one in a line to the fuel injectors or carburetor.

Note: Unless some severe and unusual condition occurs to cause a large amount of dirt to enter the gas tank, it is only necessary to replace the filter in the line.

Vehicle Power Train

A vehicle’s power train consists of components that generate and transmit power to the wheels.

- In a rear-wheel drive vehicle, the power train includes:

- The engine which generates the force which is transmitted

- The transmission in which gears adjust the engine’s RPM so as to control the torque or force which is transmitted

- A clutch (automatic or manual) which disengages the transmission from the engine to allow changing gears

- The drive shaft that transmits forces from the transmission to the components at the rear of the vehicle. These include the differential which allows the back wheels to turn at different speeds so as to maintain traction and the axle delete which transmits the force from the differential to the rear wheels.

- In a front-wheel drive vehicle, the power is transmitted from the engine through the combination of transmission-differential and then directly to the front wheels.

- In a four-wheel drive vehicle, the power is transmitted from the transmission to the transfer case that transmits power to either the rear wheels only or to both the rear and front wheels.

Vehicle Exhaust

After the gas explodes in the cylinders of the engine it is released into one or more exhaust manifolds and collect into one stream of spent gases from all the cylinders. The gases are then passed through a catalytic converter that chemically reduces the quantity of harmful pollutants and eventually passes by exhaust pipes through the muffler and resonator that reduce the noise from the explosion of gas in the engine. The gasses are then moved to the tailpipe which vents the hot gases away from the vehicle so that they will not collect underneath it.

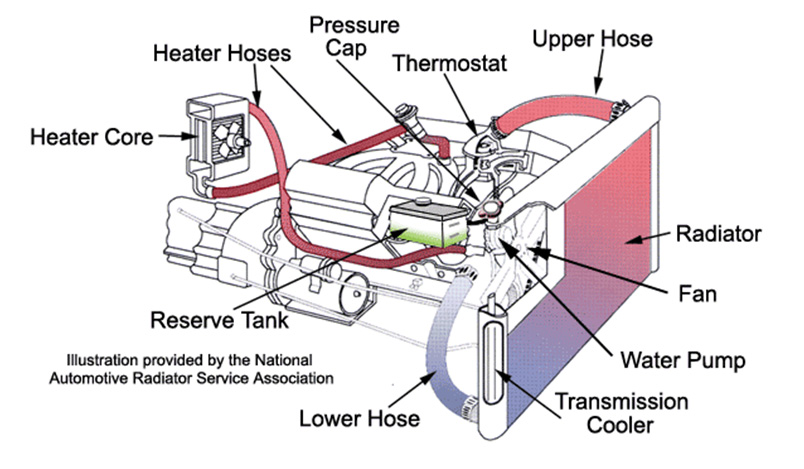

Vehicle Cooling System

The heat caused by the friction of moving engine parts and the explosion of gasoline in the cylinders is removed through the vehicle’s cooling system. The coolant flowing through the passages inside the engine absorbs the heat. The coolant is a mixture of water and chemicals that protect the cooling system from corrosion lubricate the water pump and prevent engine from freezing. The coolant is largely stored in the radiator whose main purpose is to transfer the heat from the coolant to the outside environment (air) while it is being circulated by the water pump. The radiator is cooled by air flowing through it as you drive and by the radiator fan. Most radiators have a recovery tank, which is used to capture coolant as it expands due to heat and return it to the radiator when it cools. In order to allow the engine to quickly heat up to proper running temperature, the flow of coolant is controlled by heat sensing valve called a thermostat.

Vehicle Electrical System

- The battery is your vehicle’s primary source of electrical power. When you turn your ignition switch to start your car, electricity is used to close another switch called a solenoid that transmits the large amount of current needed to turn the starter motor. Once your engine is running, power is generated by the alternator, which also keeps your battery charged. The voltage regulator controls the amount of electricity that is generated. The distributor and coil generate and deliver the very high voltage electricity needed by the individual spark plugs of your engine

Electricity is distributed throughout your vehicle by various electrical circuits for lighting, operation of electrical motors, computers that control various functions, and radio, interior cooling, heating and ventilation system. The fuses are to disable a circuit that is drawing too much current to prevent a fire and protect the components that the circuit serves.

Suspension

- The purpose of your vehicle’s suspension system is to:

- Connect the wheels to the frame and body.

- Keep the movement of your wheels from being transmitted fully to the body. This allows the driver to maintain control of the car in turns and on rough roads. It also makes riding in the car more comfortable.

- The up and down movement of the wheels is absorbed by the springs in the suspension system. Shock absorbers keep the springs from continuously bouncing.

- There are different designs for suspension systems involving various linkages, struts, joints and torsion bars.

Brakes

The purpose of brakes is to allow the driver to slow down or stop the vehicle,upon pressing down on the brake pedal. The brakes must be in top working condition, so that in an emergency the driver is able to stop completely without incident. The brake pads need to be maintained by repairing or replacing them since they get the most wear.

The purpose of brakes is to allow the driver to slow down or stop the vehicle,upon pressing down on the brake pedal. The brakes must be in top working condition, so that in an emergency the driver is able to stop completely without incident. The brake pads need to be maintained by repairing or replacing them since they get the most wear.

- There are two independent braking systems in your vehicle:

- Service brakes are used to slow your vehicle while you are driving.

- Parking brake (also referred to as the emergency brake) can also be used to slow your vehicle in an emergency, but is mainly used to hold your vehicle in one place while stopped or parked.

- When you press your brake pedal, a piston in your master cylinder forces brake fluid through hydraulic lines to pistons in the wheel cylinders at the wheels.

- There are two types of brakes:

- Drum brakes slow your vehicle by the friction of a brake shoe pushing against the drum that is rotating with the wheel.

- Disk brakes slow your car by the friction of a caliper pressing against a disc that is rotating with the wheel.

Both drum and disk brakes convert friction force to heat and if the brakes get too hot, they cease to work because they cannot dissipate enough heat. For both types of brakes, your stopping distance time is roughly proportional to the square of your speed, so if you double your speed you quadruple the distance to stop your car.

Both drum and disk brakes convert friction force to heat and if the brakes get too hot, they cease to work because they cannot dissipate enough heat. For both types of brakes, your stopping distance time is roughly proportional to the square of your speed, so if you double your speed you quadruple the distance to stop your car.

- When you are stopped and apply your brakes, they lock. It is the friction force between the tires and the road that keeps you from moving. Brakes will only slow your car while there is friction between the moving parts of your brakes.

- If the wheels are locked, as in the case of a skid, the drums or discs are not moving and there will be no friction.

- The purpose of antilock brake systems is to prevent the brakes from becoming locked by first sensing if they are locked and then automatically and rapidly releasing and applying pressure.

- If you do not have antilock brakes, you can avoid having your brakes lock by manually and rapidly releasing and then reapplying pressure to your brake pedal.

- The parking brake uses a cable rather than a hydraulic system to engage your brakes or clamp down on your drive shaft and will therefore function even if your service brakes have failed.

Since most cars on the road today have some form of Antilock Brakes (ABS), we should take a look at how they work and clear up some misinformation about them. Different manufacturers have their own versions of ABS values, specifications and part names. Always refer to the specific service and repair manuals for your vehicle.

- The ABS is a four-wheel system that prevents wheel lock-up by automatically modulating the brake pressure during an emergency stop.

- By preventing the wheels from locking, it enables the driver to maintain steering control and to stop in the shortest possible distance under most conditions.

- During normal braking, the ABS and non-ABS brake pedal feel will be the same.

- During ABS operation, a pulsation can be felt in the brake pedal, accompanied by a fall and then rise in brake pedal height and a clicking sound.

- Vehicles with ABS are equipped with a pedal-actuated, dual-brake system.

- The hydraulic system consists of the following:

- ABS hydraulic control valves and electronic control unit

- Power brake booster

- Brake master cylinder

- Necessary brake tubes and hoses

- The anti-lock brake system consists of the following components:

- Hydraulic Control Unit (HCU).

- Anti-lock brake control module.

- Front anti-lock brake sensors / rear anti-lock brake sensors.

- The hydraulic system consists of the following:

- Anti-lock Brake System (ABS) operates as follows:

- When the brakes are applied, fluid is forced from the brake master cylinder outlet ports to the HCU inlet ports. This pressure is transmitted through four normally open solenoid valves contained inside the HCU, then through the outlet ports of the HCU to each wheel. The primary (rear) circuit of the brake master cylinder feeds the front brakes. The secondary (front) circuit of the brake master cylinder feeds the rear brakes.

- If the anti-lock brake control module senses a wheel is about to lock, based on anti-lock brake sensor data, it closes the normally open solenoid valve for that circuit. This prevents any more fluid from entering that circuit.

- The anti-lock brake control module then looks at the anti-lock brake sensor signal from the affected wheel again. If that wheel is still decelerating, it opens the solenoid valve for that circuit.

- Once the affected wheel comes back up to speed, the anti-lock brake control module returns the solenoid valves to their normal condition allowing fluid flow to the affected brake.

- The anti-lock brake control module monitors the electromechanical components of the system.

- Malfunction of the anti-lock brake system will cause the anti-lock brake control module to shut off or inhibit the system. However, normal power-assisted braking remains. Loss of hydraulic fluid in the brake master cylinder will disable the anti-lock system.

- The 4-wheel anti-lock brake system is self-monitoring. When the ignition switch is turned to the RUN position, the anti-lock brake control module will perform a preliminary self-check on the anti-lock electrical system indicated by a three second illumination of the yellow ABS wanting indicator.

- During vehicle operation, including normal and anti-lock braking, the anti-lock brake control module monitors all electrical anti-lock functions and some hydraulic operations. Each time the vehicle is driven and as soon as vehicle speed reaches approximately 20 km/h (12 mph), the anti-lock brake control module turns on the pump motor for approximately one-half second. At this time, a mechanical noise may be heard. This is a normal function of the self-check by the anti-lock brake control module. When the vehicle speed goes below 20 km/h (12 mph), the ABS turns off.

- Most malfunctions of the anti-lock brake system and traction control system, if equipped, will cause the yellow ABS warning indicator to be illuminated.